Application areas

Application area

Pharmaceutical wastewater treatment

According to incomplete statistics, my country's pharmaceutical industry wastewater is discharged from 2 to 0.3 billion tons per year. Pharmaceutical wastewater contains a large number of refractory organic pollutants, many of which have certain toxicity and "three effects". If not fully treated, it will affect the balance of the ecosystem., And then affect human health and survival.

Pharmaceutical wastewater contains a large amount of suspended matter, and the suspended matter and turbidity in the water are close to zero through the efficient separation of the membrane. In addition, because the wastewater contains toxic substances, it is easy to cause sludge expansion, and the water quality of the effluent will not be affected under the action of membrane separation. In addition, the water quality and quantity of pharmaceutical wastewater have greater volatility, and the efficient interception of the membrane increases the sludge concentration, increases the treatment capacity of the reactor, and can withstand higher impact loads. From the domestic use of flat membrane MBR technology to treat pharmaceutical wastewater engineering examples, the operation of the treatment system is basically stable, the water quality is better, a large part of the waste water to achieve recycling, for enterprises to save investment, to achieve a win-win economic and environmental benefits.

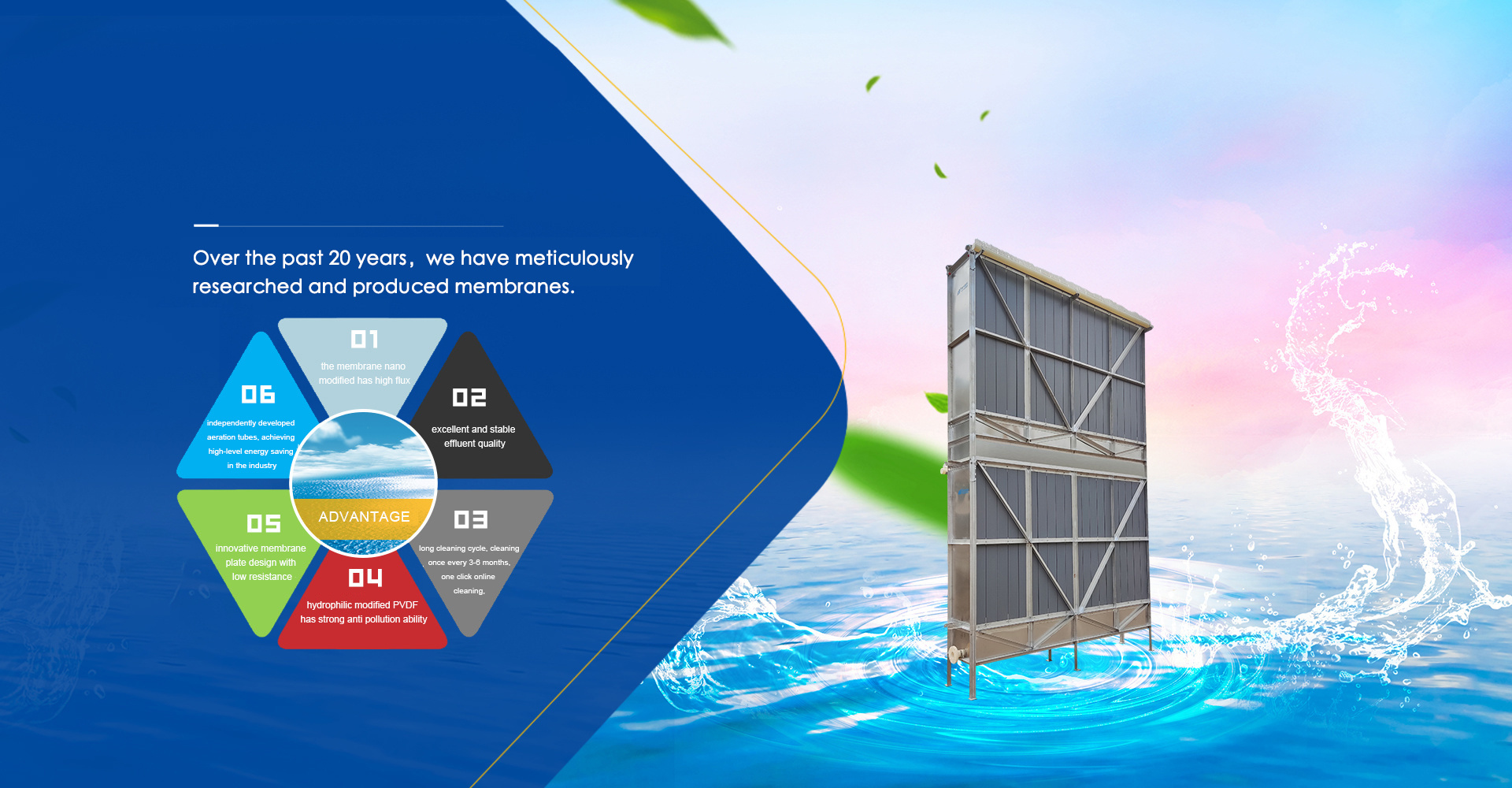

The existing engineering practice shows that the Qingda Guohua flat membrane MBR system has the following advantages in the treatment of pharmaceutical wastewater:

(1) The separation efficiency is high, and the water quality is guaranteed. Pharmaceutical wastewater contains toxic substances, which can easily lead to sludge expansion, and the effluent quality will not be affected under the action of membrane separation.

(2) The sludge concentration is high and the biochemical ability is strong. Due to the large fluctuation of the water quality and quantity of pharmaceutical wastewater, the increase of sludge concentration increases the treatment capacity of the reactor and can withstand a high impact load.

(3) The purification efficiency of refractory organic matter is improved, and the refractory organic matter in pharmaceutical wastewater is trapped in the reactor, which is beneficial to the cultivation of some obligate microorganisms.

(4) It is beneficial to the growth of nitrifying bacteria and has good NH3-N removal effect.

Contact:

Main Address: Jiahua Building, Zhongguancun Science Park, Beijing, China

Factory address:Beijing Economic and Technological Development Zone

Main Office: +86 10 62980139

Fax: +86 10 62981418

Tel:+86 10 153 0133 0853

office(US):+1 919 666 7251

E-mail:ghm@gohigher.cn

Website:http://en.gohigher-m.cn