Application areas

Application area

Petrochemical Industry Wastewater Treatment

The petrochemical industry accounts for over 5% of the total industrial water intake in China, with wastewater discharge reaching 3.37 billion tons, making up 17.8% of the national wastewater discharge. It is a typical industry with significant emissions of hard-to-treat industrial wastewater.

The wastewater generated during petrochemical production is characterized by large volumes, high concentrations of organic pollutants, and complex compositions. Pollutants often include toxic substances such as sulfur compounds, phenols, cyanides, benzene, and metal salts. Additionally, the petrochemical industry is a major water consumer. Excessive water usage and discharge not only increase operational costs but also pose a serious threat to the surrounding aquatic ecosystems. Currently, petrochemical wastewater treatment primarily follows a process of physicochemical pretreatment + secondary biological treatment + tertiary advanced treatment. However, these methods often face issues such as unstable organic pollutant removal, low treatment efficiency, and low wastewater reuse rates.

The wastewater generated during petrochemical production is characterized by large volumes, high concentrations of organic pollutants, and complex compositions. Pollutants often include toxic substances such as sulfur compounds, phenols, cyanides, benzene, and metal salts. Additionally, the petrochemical industry is a major water consumer. Excessive water usage and discharge not only increase operational costs but also pose a serious threat to the surrounding aquatic ecosystems. Currently, petrochemical wastewater treatment primarily follows a process of physicochemical pretreatment + secondary biological treatment + tertiary advanced treatment. However, these methods often face issues such as unstable organic pollutant removal, low treatment efficiency, and low wastewater reuse rates.

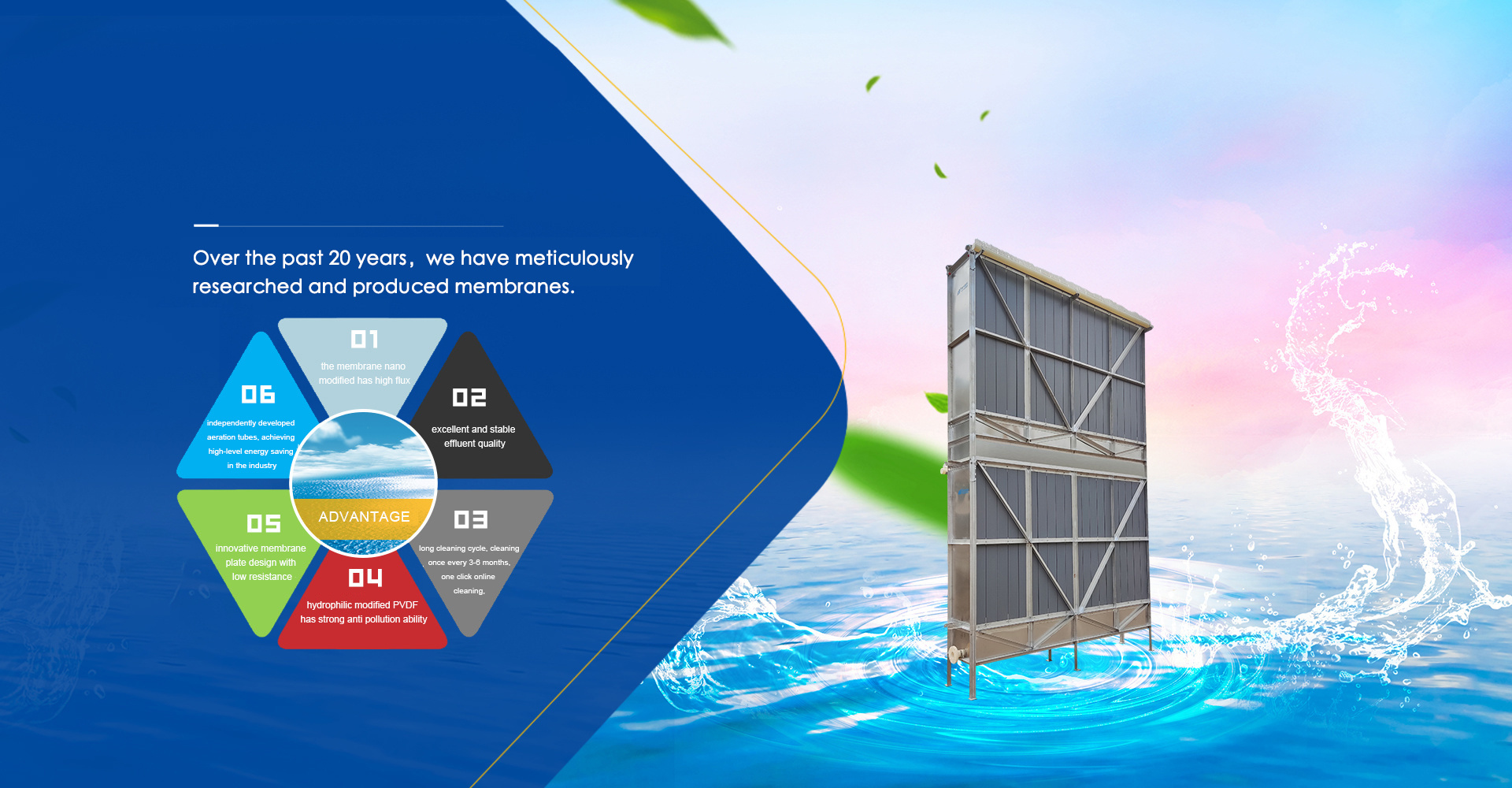

Technical Advantages Existing engineering practices demonstrate that the Go Higher’s Flat Sheet Membrane MBR System offers the following advantages in petrochemical wastewater treatment:

1. Effectively degrades organic pollutants and other nutrients in the water.

2. Features strong resistance to shock loads, high biological treatment efficiency, and a small footprint.

3. For wastewater with moderate conductivity, the effluent treated by the flat sheet membrane MBR can be directly reused in cooling and circulating water systems. This plays a crucial role in reducing pollutant emissions, improving wastewater reuse rates, and ensuring the safety of the reuse system.

Contact:

Main Address: Jiahua Building, Zhongguancun Science Park, Beijing, China

Factory address:Beijing Economic and Technological Development Zone

Main Office: +86 10 62980139

Fax: +86 10 62981418

Tel:+86 10 153 0133 0853

office(US):+1 919 666 7251

E-mail:ghm@gohigher.cn

Website:http://en.gohigher-m.cn