Comparison of the advantages of MBR flat membrane and hollow fiber membrane!

Release time:

2021-11-10

Flat membrane separation technology, as a high-efficiency and low-pollution purification technology integrating separation and concentration, has the characteristics of simple operation, convenient maintenance, low energy consumption, and strong adaptability. It has gradually been widely used by environmental protection workers and people who care for the environment. Awareness, cognition and application in sewage treatment in related industries.

Flat membrane separation technology, as a high-efficiency and low-pollution purification technology integrating separation and concentration, has the characteristics of simple operation, convenient maintenance, low energy consumption, and strong adaptability. It has gradually been widely used by environmental protection workers and people who care for the environment. Awareness, cognition and application in sewage treatment in related industries.

Comparison of Advantages of 1. Flat Membrane and Hollow Membrane

(1) Better anti-pollution performance.

Compared with the hollow fiber membrane bioreactor, the flat membrane bioreactor can maintain the stable operation of high flux (flux is the water yield of the membrane) at a higher activated sludge concentration, and the requirement for pretreatment is lower.

In the process of actual use, although there will be grille, hair removal machine and other equipment in the pretreatment facility, some objects such as hair will inevitably enter the aeration tank.

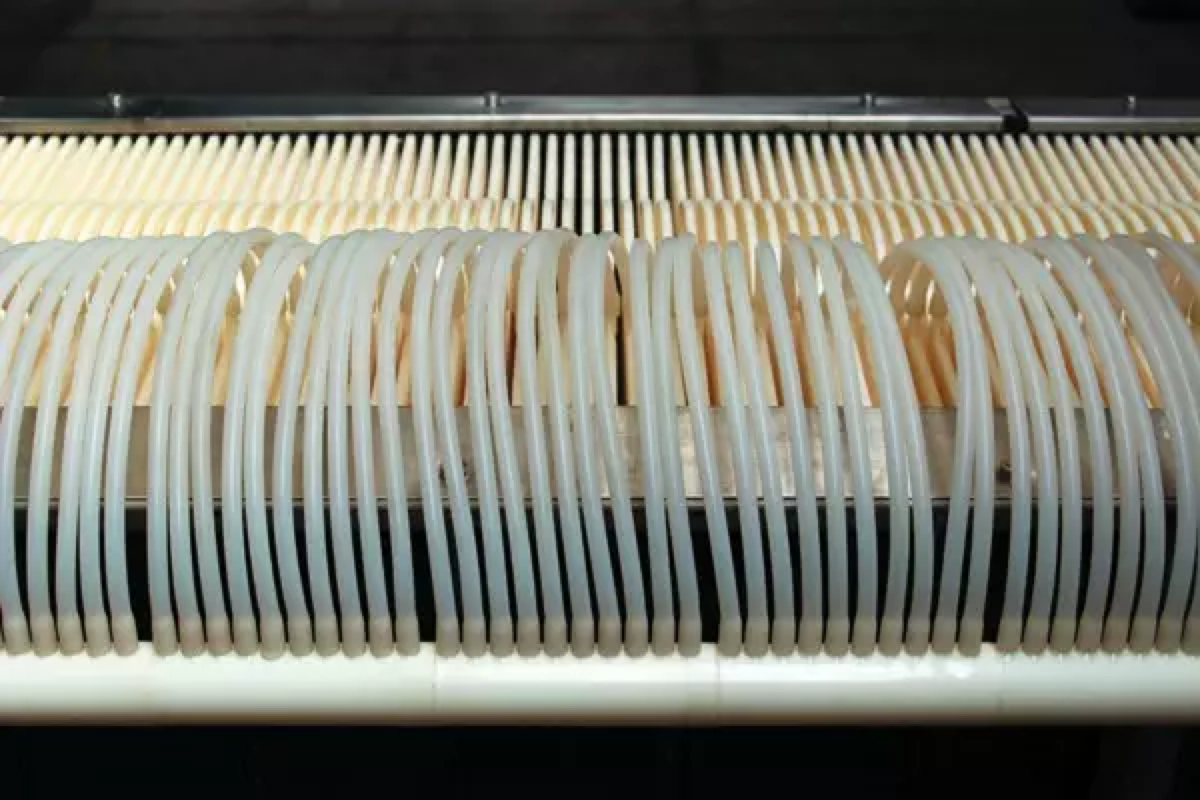

When the hollow fiber membrane bioreactor is running, the membrane filaments are always in a state of shaking under aeration, so these hairs can easily make the membrane filaments entangled together. When the sludge concentration reaches a certain level, mud lumps will appear, causing more and more membrane filaments to entangle together, greatly reducing the effective membrane area of the hollow fiber filaments, causing a sharp decline in membrane flux, and such problems are also difficult to repair, usually it can only be replaced.

The applicable activated sludge concentration (MLSS) of flat membrane bioreactor is in the range of 6000-10000mg/L, which is much higher than that of hollow fiber membrane reactor. The structure of flat membrane module is composed of multiple membrane elements arranged and assembled, which realizes controllable gap between membranes, facilitates on-line cleaning of membrane surface by gas-liquid mixed flow, and has excellent anti-pollution performance.

In addition, the flat membrane bioreactor can well remove the attachments on the membrane surface by adjusting the aeration intensity at the bottom of the module and the scouring effect of the air-water mixture on the membrane surface. Even if the membrane surface is silted up due to factors such as excessive sludge viscosity in a short period of time, the membrane can be taken out in a single piece and assembled into the membrane module after removal by low-pressure water gun flushing, so that the membrane can operate effectively for a long time, hollow fibers cannot be cleaned by this method.

(2) good mechanical stability, no broken wire phenomenon.

In the actual use process, hollow fiber membrane module will inevitably occur broken wire phenomenon, including two reasons:

One is the uneven wall thickness caused by defects in the spinning process. Of course, this situation is relatively rare and can be further avoided by purchasing high-quality products;

The second is the root fracture caused by the fatigue of the spinning material.

Hollow fiber filaments need to be sealed with epoxy resin where the components are connected at both ends. Due to the capillary phenomenon of the fiber filament itself, it will definitely suck a small section at the root. Due to aeration, the hollow fiber will always be in a large vibration phenomenon in the working state, which will cause material fatigue in its root in the long run. Epoxy resin itself is a brittle material. Once the broken wire caused by material fatigue occurs, it is often large-scale. For membrane bioreactor, the damage is fatal, which will not only seriously affect the water quality of the effluent, it also results in the scrapping of the entire assembly.

The difference is that the flat membrane has a non-woven fabric as a diversion layer, 3mm ~ 5mm ABS plate as a support layer, so the strength is much higher than the hollow fiber, there will be no similar phenomenon, can fully guarantee the quality of water quality.

(3) The cleaning method is more convenient and the cleaning cycle is longer.

The cleaning of membrane modules is divided into online cleaning and offline cleaning.

The online cleaning of the hollow fiber membrane is more frequent, and the cleaning process is complicated, and it is necessary to pressurize the prepared chemical agent into the membrane filament through the dosage pump to complete the cleaning. On the one hand, the on-line cleaning of flat membrane is realized by aeration in operation, on the other hand, it is realized by on-line chemical cleaning.

The flat membrane bioreactor can effectively scour the membrane surface by controlling the aeration rate of the aeration system at the bottom of the module, so as to prevent excessive sludge deposition on the membrane surface during the suction process and control the pollution of the membrane surface during operation. The chemical cleaning (on-line cleaning) of the flat membrane module is also simpler, only the prepared agent is poured back into the diaphragm from the suction port and soaked for a period of time.

The off-line cleaning of the hollow fiber membrane must be lifted out of the entire membrane module, placed in the cleaning tank, and soaked with chemical agents. The cleaning of the flat membrane can either lift the membrane module out for cleaning or pull out the membrane element for cleaning. The diversity of off-line cleaning methods of flat membrane also solves the problem that the project site is narrow and should not be lifted.

At the same time, compared with the hollow fiber-membrane bioreactor, the cleaning cycle of the flat membrane bioreactor is longer, and the cleaning cycle can reach more than 3 months, and if the working pressure is always in a relatively low state, it may not even be cleaned. The flat membrane module can also recover the membrane flux by physical cleaning methods such as low-pressure water gun flushing, which is almost impossible for hollow fiber membranes.

(4) long life, low operating costs

According to incomplete statistics, the average life span of hollow fiber membranes on the market is about 4 years in the treatment projects of domestic sewage, municipal wastewater and domestic sewage, and about 2 years in industrial wastewater, medical wastewater and other projects. it can hardly be used in landfill leachate, electroplating wastewater, refractory organic wastewater and other projects.

The average life of flat membrane on the market in the treatment of domestic sewage, municipal wastewater and domestic sewage is about 5 years, and the average life in industrial wastewater, medical wastewater and other projects is about 3 years. It can be applied to landfill leachate, electroplating wastewater, refractory organic wastewater and other projects.

The replacement cycle of the flat membrane is longer than that of the hollow fiber membrane, the operating cost is greatly reduced, and the good operating condition is ensured. At the same time, the flat film can be replaced by a single sheet, and the replacement cost is relatively lower.

(5) diaphragm replacement process is simple

Due to the unique design of the flat membrane module, the diaphragm can be replaced in a single sheet without replacing the bracket in the process of diaphragm damage. The middle fiber membrane wire broken wire reaches a certain number, the entire component is scrapped, need to replace the entire membrane module, the cost will be greatly increased.

Key words:

Related News

2024-12-31

Contact:

Main Address: Jiahua Building, Zhongguancun Science Park, Beijing, China

Factory address:Beijing Economic and Technological Development Zone

Main Office: +86 10 62980139

Fax: +86 10 62981418

Tel:+86 10 153 0133 0853

office(US):+1 919 666 7251

E-mail:ghm@gohigher.cn

Website:http://en.gohigher-m.cn